Augmenta, a Toronto-based company behind a platform that automates the design of building systems with artificial intelligence (AI), is focused on reducing time, budgets and uncertainty in construction as much as it is on waste and energy.

Founded in 2018 by two former Autodesk employees — Francesco Iorio and Aaron Szymanski — the company’s technology can automatically generate models for the inner workings of a building. It is made to significantly speed up the manual work of routing and coordinating a building’s electrical system, for example, while minimizing the risks of conflicting systems and human error in design.

Built over six years of development, the Augmenta Construction Platform has been shown to slash the time spent on modelling and routing by 60 to 70 per cent. Its use helps to lower construction waste, which addresses the energy and carbon consumption of building projects.

Iorio and Szymanski formed the company to “empower people in the construction industry to design buildings more efficiently at a lower cost, and then ultimately, enabling a future of sustainable buildings,” Johnnie Kern, Augmenta’s director of marketing, told Sustainable Biz Canada in an interview.

The company’s potential impact on sustainability has caught the attention of the Cleantech Group, which listed Augmenta on the Global Cleantech 100 list for the first time. The San Francisco-based organization says AI solutions like Augmenta’s show how the technology is “being used to accelerate and design solutions” in the cleantech sector.

Taking on pre-construction problems

The types of buildings Augmenta’s clients work on have miles of internal building systems (electrical, plumbing, HVAC) that must be balanced for space and energy, Kern said. Professionals often spend weeks or months to model out where electrical conduits should be placed, highlighting the difficulty of the task.

During the building’s pre-construction phase when the systems are mapped out, redesigns and errors often pop up, Kern said. As a result, a large volume of construction waste is generated and more materials are needed to continue the project.

The production and disposal of construction materials are a large contributor to the waste and carbon emissions of the buildings sector.

A 2025 study in the journal Building and Environment suggests the production of building materials is responsible for 80 per cent of the greenhouse gas emissions of construction waste. Circular Construction Canada estimates four million tonnes of construction waste is generated per year in the country, with only 16 per cent diverted from landfill.

In light of this problem, the Augmenta Construction Platform was made to accelerate “the time to a fully coordinated model,” Kern said.

How the Augmenta Construction Platform works

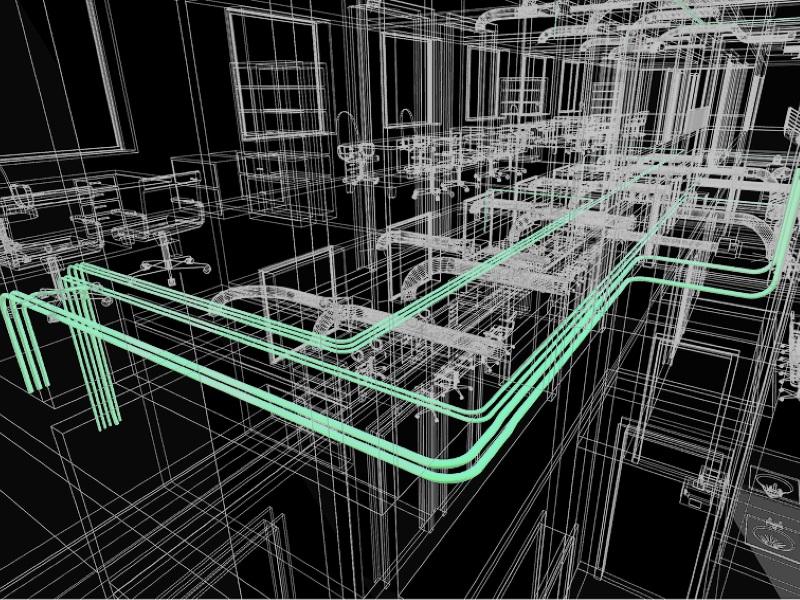

The Augmenta Construction Platform combines a spatial AI (one that can work in 3D environments) with algorithms and machine learning methods to produce layouts of building systems for data centres, hospitals and schools. The platform was developed to minimize or eliminate clashing building systems and errors, cutting down on the need to redesign a building.

“It’s not ChatGPT bolted onto something,” Kern said about the platform. At its core is not a generative AI, but a proprietary technology focused on construction designs, he explained. Issues such as hallucinations or nonsensical designs that have cropped up with generative AI will not happen with Augmenta’s platform, he explained, further proven by its real world uses.

The company says the platform can boost the productivity of electrical contractors by three times. It has also shrunk material waste by between 15 and 25 per cent in projects, Kern said.

For example, the Augmenta Construction Platform was used in the planning of the Mt. Hope Elementary School in Michigan. The company’s technology helped speed up the design process by 25 per cent and reduced material waste by 15 per cent.

'A real honour' to be on Cleantech 100 list

A team of over 50 employees today, Augmeta services clients in Canada and the U.S. The company plans to grow its presence globally over the coming years, Kern said.

The Augmenta Construction Platform is currently supporting only electrical systems, but the company plans to add mechanical, plumbing and structural systems in the future. Its goal is to extend its service to engineers and general, mechanical and plumbing contractors.

Augmenta has raised tens of millions of dollars to date. In 2023, it raised almost $16 million in a seed extension round. Two years later, it raised $14.4 million to develop its technology. This year, the company plans to do more fundraising, Kern said.

When Augmenta heard it made the Global Cleantech 100, the company was “thrilled.”

“We feel like there’s a huge opportunity to change the economics for the construction industry. There’s a lot of waste. To be included in that list is a real honour,” Kern said.